Continuous assessment for a 300 level Mass communication student in UNILAG

Name: Adebayo Moyomade Favour

Matric number:230902027

Digital Twins: Concept, Evolution, and Applications

Introduction

As organizations increasingly rely on data to drive innovation and operational efficiency, the ability to understand, monitor, and predict the behavior of physical systems has become essential. One technology that has emerged at the intersection of data analytics, simulation, and the Internet of Things (IoT) is the Digital Twin.

Digital twins enable real-time monitoring, simulation, and optimization of physical assets by creating dynamic virtual representations that evolve alongside their real-world counterparts.

This article presents a comprehensive overview of digital twins by examining their concept, historical evolution, operational framework, benefits, applications across industries, challenges, and future prospects.

Concept and Definition of Digital Twins

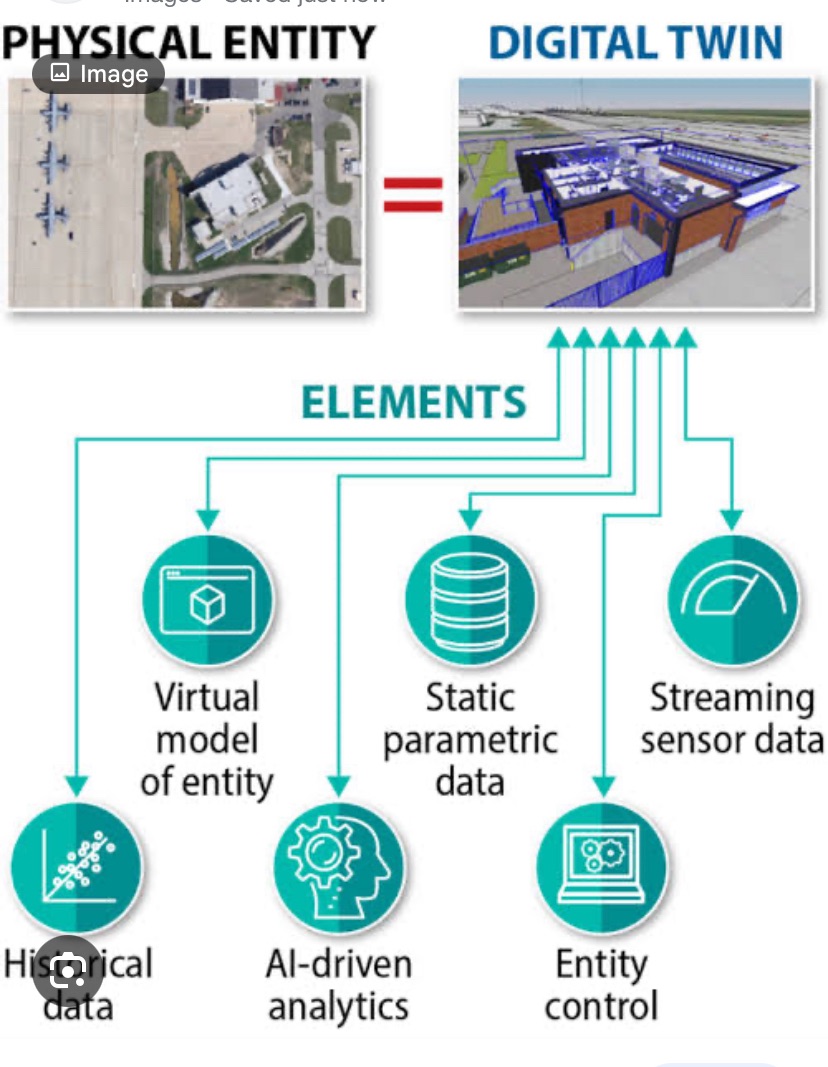

A Digital Twin is a virtual representation of a physical object, system, or process that is continuously updated with real-time data throughout its lifecycle. It mirrors the state, behavior, and performance of its physical counterpart, allowing organizations to analyze present conditions, predict future outcomes, and test alternative scenarios without directly interfering with the physical asset.

Unlike traditional simulation models, which are typically static and based on assumptions, digital twins are dynamic and data-driven, operating through a continuous feedback loop between the physical and digital environments.

Historical Origins and Evolution of the Digital Twin Concept

The origins of the digital twin concept can be traced to early system replication practices in aerospace engineering. During the 1960s Apollo space missions, the National Aeronautics and Space Administration (NASA) used mirrored physical systems on Earth to simulate spacecraft conditions and resolve technical challenges remotely. Although these systems were not digital, they embodied the fundamental idea of creating a counterpart to monitor and predict system behavior.

The modern digital twin concept was formally introduced in 2002 by Dr. Michael Grieves, a professor at the University of Michigan, within the framework of Product Lifecycle Management (PLM). Grieves proposed a model consisting of:

- A physical product

- A virtual product

- Data connections linking both across the product lifecycle

This model is widely regarded as the first formal articulation of the digital twin concept.

Around 2010, NASA further refined the idea by defining digital twins as integrated, multi-physics, and multi-scale simulations that mirror the life of a physical system in real time. This marked a shift from theoretical models to practical, data-enabled implementations.

From 2015 onward, advances in IoT, cloud computing, artificial intelligence, and big data analytics accelerated the adoption of digital twins across multiple industries. Major technology and industrial firms began developing commercial digital twin platforms, positioning the technology as a core element of Industry 4.0.

How Digital Twins Work

Digital twins operate through the integration of several interconnected technological components:

- Physical Asset or Process

The real-world entity being replicated, such as a machine, building, human organ, or supply chain. - Sensors and IoT Devices

Sensors collect real-time data on variables such as temperature, pressure, vibration, energy consumption, and operational status. - Data Infrastructure

Data is transmitted and stored through cloud or edge computing systems for processing and analysis.

Types of Digital Twins

Digital twins can be classified based on their scope and level of complexity:

- Component Twins: Represent individual parts of a system

- Asset Twins: Model complete physical assets

- System or Unit Twins: Capture interactions among multiple assets

- Process Twins: Represent complex workflows such as supply chains or operational processes

Benefits of Digital Twins

The adoption of digital twins offers several key advantages, including:

- Predictive maintenance, which reduces unplanned downtime

- Improved decision-making through real-time insights

- Cost efficiency by minimizing physical prototyping and experimentation

- Enhanced innovation through rapid testing and optimization

Applications of Digital Twins Across Industries

Digital twins are increasingly applied across various sectors:

- Manufacturing: Optimization of production processes and quality control

- Healthcare: Personalized treatment planning and medical simulations

- Smart Cities: Urban planning, traffic management, and energy optimization

- Energy and Utilities: Monitoring power generation and grid performance

- Challenges and Limitations

- Despite their advantages, digital twins face several challenges:

- High implementation and infrastructure costs

- Data security and privacy concerns

- Integration difficulties with legacy systems

Conclusion

- Digital twins represent a transformative approach to designing, monitoring, and optimizing physical systems. From their early roots in aerospace engineering to their formal conceptualization by Dr. Michael Grieves in 2002, digital twins have evolved into a foundational technology for modern, data-driven organizations. By bridging the physical and digital worlds, they enable smarter decision-making, reduced operational risks, and continuous innovation.

References (APA Style)

Grieves, M. (2002). Product lifecycle management: Driving the next generation of lean thinking. McGraw-Hill.

Grieves, M., & Vickers, J. (2017). Digital twin: Mitigating unpredictable, undesirable emergent behavior in complex systems. In Transdisciplinary perspectives on complex systems (pp. 85–113). Springer.

NASA. (2010). Modeling, simulation, information technology & processing roadmap. National Aeronautics and Space Administration.